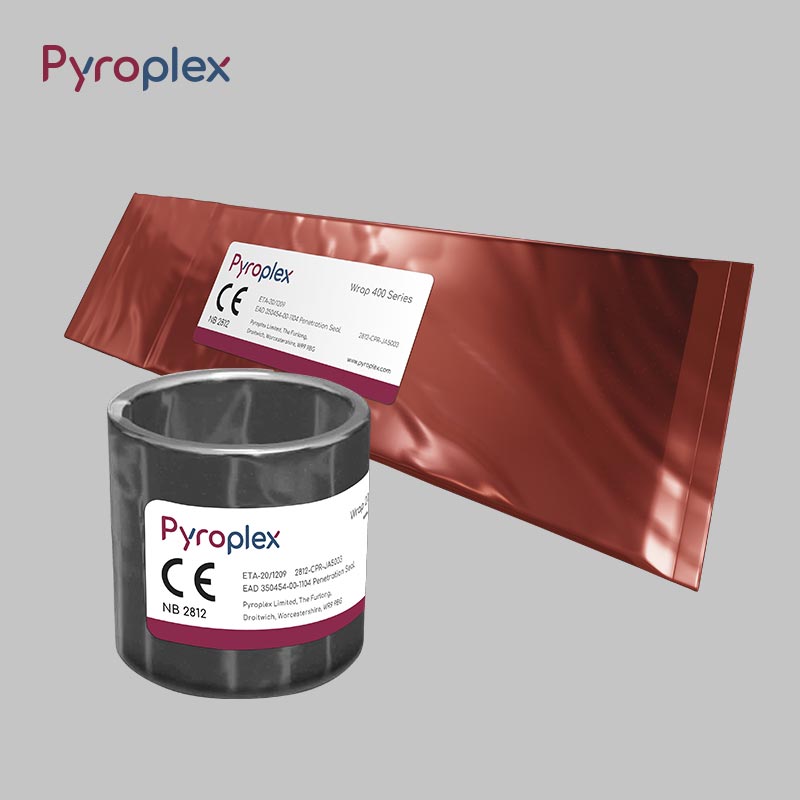

CE Marked Pipe Wraps

Application: Service penetrations – plastic SWD systems

Fire Resistance Period: up to EI 240

Insulation/integrity: Insulation and integrity

Test Standard: BS EN 1366-3

Approval Type: CE Mark 2812 – CPD-JA5003/ETA 20/1209

Pyroplex CE Marked Pipe Wraps have been specifically designed to reinstate the fire resistance of a wall or floor which has been penetrated by services such as plastic flammable pipes used in soil, waste and drainage services.

Pyroplex CE Marked Pipe Wraps are available in two fire ratings; 2 hour and 4 hour. To fit, simply fix wrap around the pipe using adhesive tab and slide along pipe into wall/floor cavity. After insertion the cavity around the pipe can be made good with filler.