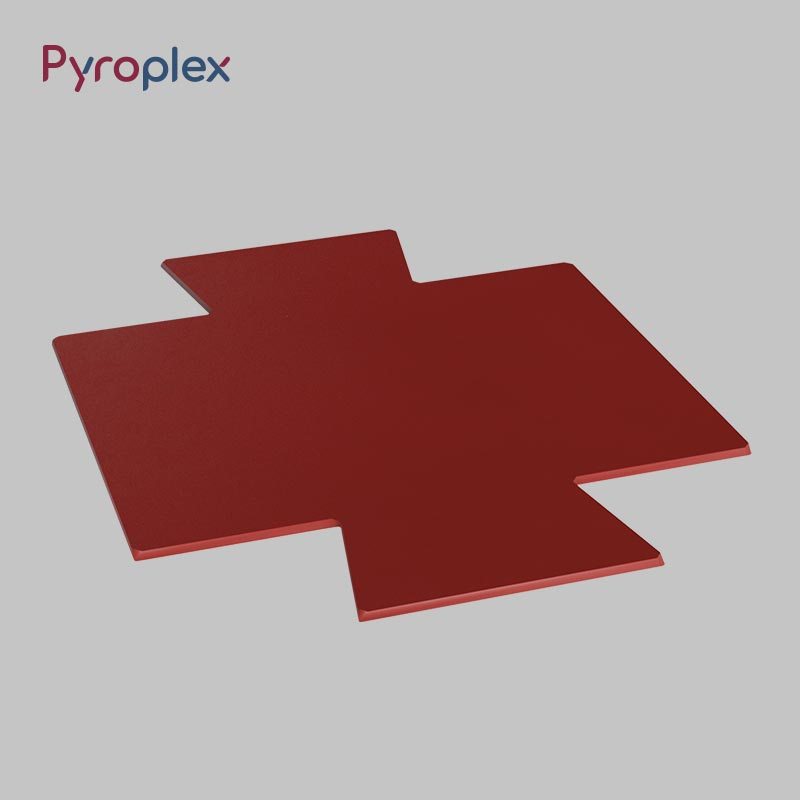

Putty Pads

Application: Penetrations

Fire Resistance Period: 120 minutes

Insulation/integrity: EI120

Test Standard: BS EN 1364:1 and BS EN 1363:1

Putty Pads are pre-cut ablative pads which have been specifically designed to reinstate the fire performance of the compartment wall when penetrated by electrical outlets, thereby reducing the need for additional backing materials. They provide a fast, efficient and clean method of achieving the required fire and acoustic ratings as required by Building Regulations Approved Documents.