Intumescent Acrylic Sealant

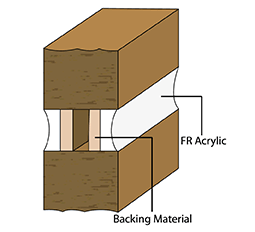

Pyroplex Intumescent Acrylic Sealant is a one-part high modulus, halogen free material. The product is primarily designed for use in internal application. It is suitable for perimeter pointing around services and for use in low movement linear joints in walls and floors.

Pyroplex Intumescent Sealant can provide up to 240 minutes fire resistance integrity depending on application and backing material required. The material is compatible with common building materials.

View our full range of fire sealants

Application: Linear gap joint – movement joints

Fire Resistance Period: up to 240 minutes

Insulation/integrity: Integrity and insulation depending upon backing materials

Test Standard: BS 476: Part 20/22, BS EN 1366-4

Approval Type: IFC Certificate No. IFCC1366, EN Classification: EN13501-2