In 2011-12, there were 380 fire related fatalities in Britain. Over half of these fatalities were partly or wholly due to people being overcome by smoke or toxic fumes. (Fire Statistics, Great Britain, 2011-2012, Department for Communities and Local Government)

The Requirement for Smoke Control

The requirement for fire door smoke compliance is indicated in these documents by the suffix S applied to the fire door classification. For example, a 30-minute fire resisting door is designated FD30 and when this is required as a smoke control door, it is designated FD30S. The smoke control required in the UK currently relates only to cold (ambient temperature) smoke. When tested in accordance with EN 1634-3:2004, the classification or designation will be defined as Sa (ambient smoke control).

There is no current requirement in the UK for control of warm or hot smoke, although the activation of any intumescent strips when subjected to fire will reduce the flow of smoke.

The smoke control criterion required in the United Kingdom is 3m3 of air loss per hour per linear metre of joint between door leaves and the doorframe or transom when measured at 25Pa pressure. The test procedure prescribes that during test, the gap between the bottom edge of the door leaf and the floor or threshold is sealed. The reason for this is to acknowledge that a uniform pressure is unlikely to be experienced over the complete face of a door in service and the sealing of the bottom of the door compensates for a reduction in pressure which is likely to be experienced.

It should be understood, however that BS 5588 defines the actual bottom edge arrangements that are permitted in use.

The Problem

In a fire situation, the production of smoke and toxicity is directly related to the ignitability, heat release and potential toxicity of the elements within the given area. All materials, from soft furnishings, fabrics, furniture and carpets will emit varying types and concentrations of smoke production.

To put all this into context, the permitted air/smoke leakage through a typical single leaf FD30S door with perimeter door gaps of 3mm is 15m3/hour whilst without smoke seals, the same door would leak 200m3/hour.

In addition large perimeter door gaps, over 3mm, have the potential to fill an escape corridor within minutes, rendering the escaping occupants effectively blind. In this situation, emergency lighting or the presence of natural lighting would be non-effective.

The Solution

To comply with the guidance given in the Approved Documents, supplementary sealing systems can significantly improve and reduce the amount of leakage through the doorset assembly. The Building Regulations ADB specify that the doorset assembly should demonstrate compliance with either BS476: Part 31.1 or BS EN 1634: Part 3:2004.

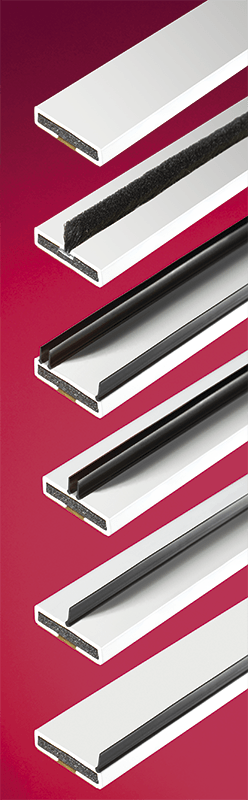

Pyroplex Fire Smoke and Acoustic seals already hold test evidence to BS476: Part 31.1 however we have enhanced our test portfolio for the following fire door strips and test them in accordance BS EN 1634-3: 2004:

- Pyroplex Single Flipper

- Pyroplex Side Flipper

- Pyroplex Twin Flipper

- Pyroplex Triple Flipper

- Pyroplex Pile

Full technical, material and safety data for our products is available to download. Furthermore, the test results are available on request. Contact Pyroplex.

- New Product Launch – 200 Series SL Pipe Collar - 9th September 2019

- Pyroplex in the News - 12th July 2019

- Pyroplex at ARCHIDEX 2019 Malaysia - 5th July 2019